Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

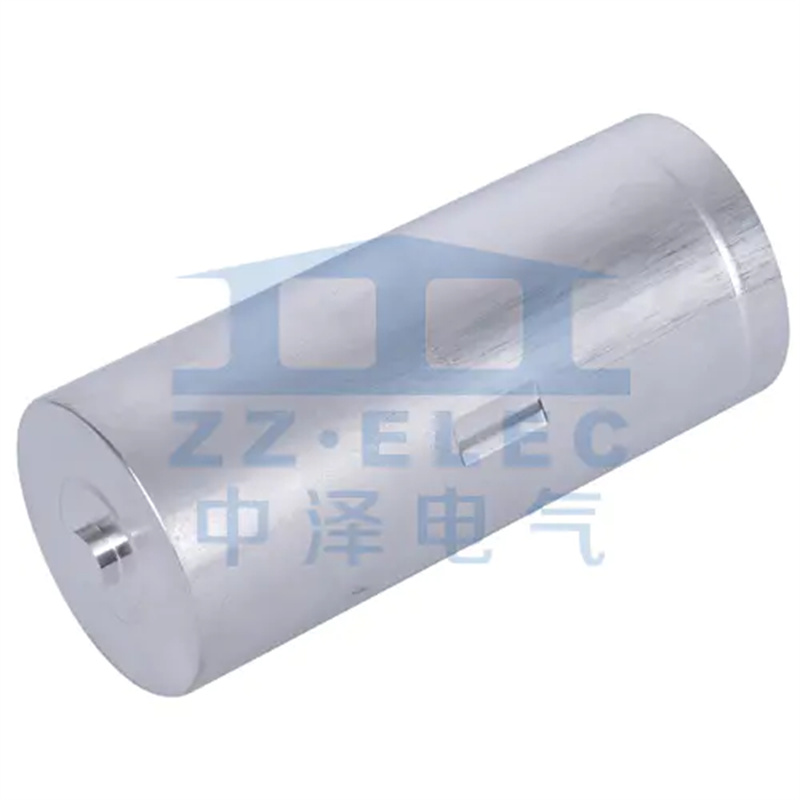

In the rapidly evolving landscape of renewable energy and electric mobility, the efficiency and reliability of energy storage systems are paramount. As the industry pivots towards high-performance solutions, the role of the New Energy Super Capacitor Cylindrical Shell has become increasingly critical. These components are not merely containers; they are engineered safety housings that protect the sensitive electrochemical internals from environmental stressors while ensuring optimal thermal management. For procurement managers and engineers in the new energy sector, selecting the right cylindrical enclosure is a decision that impacts the longevity, safety, and overall performance of the energy storage unit. This article delves into the technical specifications, material sciences, and manufacturing excellence required to produce superior cylindrical shells for next-generation supercapacitors.

The choice of material for a capacitor housing is the first line of defense against operational failure. In demanding applications such as automotive braking systems or wind turbine pitch control, the housing must withstand mechanical vibration, thermal cycling, and exposure to corrosive elements. To address these challenges, the industry has increasingly focused on corrosion resistant capacitor housing for new energy. These specialized housings utilize advanced metallurgical treatments to resist oxidation and degradation, ensuring that the capacitor maintains its integrity over thousands of charge-discharge cycles. By selecting alloys with high corrosion resistance, manufacturers can significantly extend the service life of the energy storage module, reducing the total cost of ownership for end-users.

Furthermore, the physical properties of the material play a crucial role in thermal dissipation. Aluminum alloy cylindrical supercapacitor case designs have emerged as the industry standard due to aluminum's exceptional strength-to-weight ratio and superior thermal conductivity. Unlike heavier steel alternatives, aluminum allows for efficient heat transfer away from the core, which is vital for maintaining the electrochemical stability of supercapacitors. This lightweight characteristic is particularly beneficial in the automotive and aerospace sectors, where reducing mass directly correlates to improved energy efficiency.

When evaluating material options for manufacturing, engineers often weigh the benefits of aluminum against stainless steel. While stainless steel offers superior hardness, aluminum offers the best balance of thermal performance and weight savings for high-frequency applications.

td>

| Property | Aluminum Alloy | Stainless Steel |

| Thermal Conductivity | High (Excellent for heat dissipation) | Low to Moderate (Retains heat) |

| Weight | Lightweight (Approx. 2.7 g/cm3) | Heavy (Approx. 7.9 g/cm3) |

| Machinability | Difficult (Harder tooling required) | |

| Cost | Cost-effective (Lower raw material cost) | Expensive (High raw material cost) |

As energy densities increase, the electrical and mechanical specifications of the housing must adapt accordingly. Energy storage cylindrical supercapacitor shell design is a complex process that requires strict adherence to dimensional tolerances and safety standards. One of the primary design considerations is insulation. Since supercapacitors operate at varying voltages, the shell must provide reliable electrical insulation to prevent short circuits, especially in densely packed battery modules. This often involves the application of specialized polymer coatings or insulating sleeves that do not compromise the thermal properties of the metal shell.

In addition to insulation, high voltage supercapacitor shell design necessitates robust sealing mechanisms. High-voltage applications generate significant internal pressure and heat, which can lead to electrolyte leakage if the enclosure is not perfectly sealed. Advanced crimping technologies and laser welding are employed to create a hermetic seal that can withstand extreme internal pressure without compromising the structural integrity of the can. The precision of the crimp, the thickness of the wall, and the quality of the insulating gasket are all variables that must be meticulously controlled during the manufacturing process.

To visualize the distinct requirements for different application tiers, we can compare the design specifications of standard low-voltage shells versus high-performance high-voltage shells.

td>

| Design Feature | Standard Low-Voltage Shell | High-Voltage Shell |

| Wall Thickness | Thick (Enhanced structural integrity) | |

| Insulation Requirement | Basic coating or sleeve | Multi-layer insulation with high dielectric strength |

| Sealing Method | Standard crimping | Laser welding or double-seam crimping |

| Pressure Rating | Standard atmospheric pressure tolerance | High pressure tolerance for volatile electrolytes |

The transition from prototype to mass production requires a manufacturing partner with deep technical expertise and scalable capacity. For businesses looking to develop custom solutions, partnering with a specialized custom supercapacitor enclosure manufacturer offers significant advantages. These manufacturers possess the tooling capabilities and process engineering know-how to produce shells that meet exacting customer specifications. Whether it is a unique diameter, a specific alloy composition, or a bespoke surface finish, a specialized OEM can tailor the production line to meet diverse application needs.

Our company stands at the forefront of this manufacturing sector, utilizing state-of-the-art stamping presses and automated inspection systems to deliver unparalleled quality. We understand that in the new energy sector, consistency is key. By leveraging advanced quality control protocols such as automated optical inspection (AOI) and helium leak testing, we ensure that every New Energy Super Capacitor Cylindrical Shell that leaves our facility meets the highest standards of safety and performance. This commitment to manufacturing excellence allows our clients to integrate our components into their systems with confidence, knowing that their energy storage solutions are built on a foundation of reliability.

Understanding the differences between a standard supplier and a true OEM partner can help procurement teams make better sourcing decisions.

td>td>td>

| Capability | Standard Supplier | OEM Manufacturer |

| Customization | Full customization of dimensions and materials | |

| Technical Support | Engineer-to-engineer collaboration on design optimization | |

| Production Scale | Limited stock availability | High-volume production scalability |

| Quality Control | In-house laboratory testing and certification |

The most common materials used are high-grade aluminum alloys, such as 3003 series, due to their excellent conductivity and lightweight properties. However, for more extreme environments, stainless steel may be used for enhanced durability. Aluminum alloy cylindrical supercapacitor case options are generally preferred for their balance of performance and cost-effectiveness in electric vehicles and renewable energy applications.

The cylindrical geometry is ideal for distributing internal pressure evenly and maximizing volume efficiency. It facilitates efficient stacking in module configurations and is easier to seal hermetically compared to prismatic shapes. This design is crucial for energy storage cylindrical supercapacitor shell applications where space optimization is a priority.

Yes, a specialized custom supercapacitor enclosure manufacturer can produce shells with specific dimensions, wall thicknesses, and surface coatings. Custom coatings, such as insulating varnishes or corrosion-resistant paints, can be applied to meet specific operational requirements or environmental standards.

Corrosion resistance is achieved through the selection of advanced alloys and the application of protective surface treatments. Corrosion resistant capacitor housing for new energy often involves chemical passivation or anodizing, which creates a protective oxide layer on the metal surface, preventing rust and degradation from humidity or industrial pollutants.

Absolutely. High-voltage applications require shells with enhanced insulation properties and robust sealing. High voltage supercapacitor shell design incorporates thicker insulating layers and precision welding to prevent electrical arcing and leakage, ensuring safety and reliability in demanding power electronics.