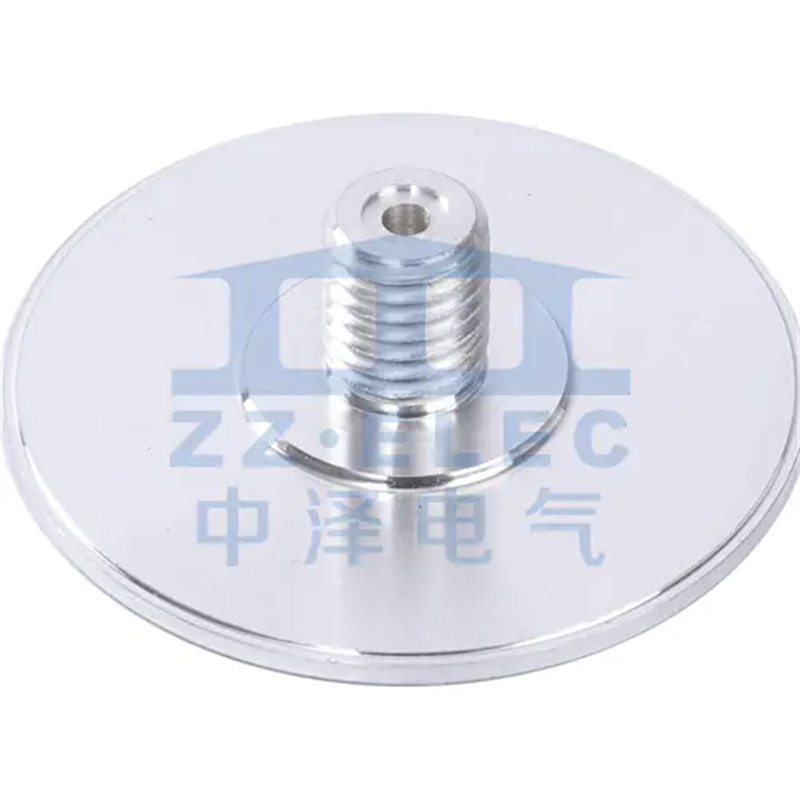

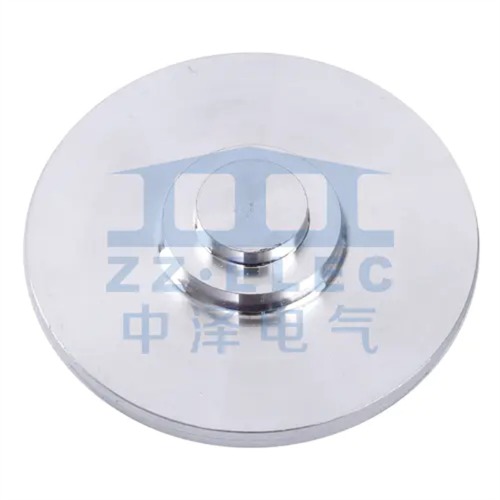

Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

In the world of engineering and manufacturing, some components are designed for flashy performance, while others perform a vital, often overlooked role in ensuring safety, reliability, and longevity. The cover plate falls firmly into the latter category. At its essence, a cover plate is a flat or slightly formed piece of material—metal, plastic, or composite—designed to seal an opening, enclose a compartment, or provide a finished face to a piece of equipment. Its functions are deceptively simple yet profoundly important: it protects sensitive internal components from environmental contaminants like dust, water, and physical impact; it safeguards users from accidental contact with live electrical parts or moving mechanisms; it can provide structural rigidity to an assembly; and it contributes significantly to the final aesthetic of a product. From the humble junction box in a home to the complex housing of a lithium-ion battery pack in an electric vehicle, the cover plate is a fundamental building block. Selecting the right one requires careful consideration of material science, mechanical design, environmental standards, and manufacturing processes. This guide delves into the specifics of cover plates, exploring their types, applications, standards, and the advanced manufacturing technologies that bring them to life, empowering you to specify the perfect component for your project.

A cover plate is more than just a lid. Its design is dictated by a clear set of functional requirements. The primary function is invariably protection—creating a barrier between the internal environment of a device and the external world. This can mean keeping contaminants out (dust, liquids, chemical vapors) or keeping components in (sealing fluids or gases). Secondly, it often serves as a safety guard, preventing accidental contact with hazardous parts. Thirdly, it can act as an electromagnetic interference (EMI) or radio frequency interference (RFI) shield when made from conductive materials and properly grounded. Finally, it provides the finished interface that users see and interact with, making its appearance and feel important for product design. Key design parameters include material selection (for strength, corrosion resistance, conductivity, and weight), thickness (for rigidity and durability), overall dimensions and tolerances, the method of attachment (screws, clips, hinges, welding), and any required apertures for displays, switches, or connectors.

The diversity of cover plate applications has led to specialized types, each optimized for its unique role. Material choice and fabrication method are directly tied to the performance demands of the application.

Perhaps the most common and safety-critical application is the cover plate for electrical panel. These plates are designed to meet strict international standards (like IEC 61439 or UL standards) for electrical safety. They must be made from durable, non-conductive, or properly grounded conductive materials. Key features often include high-impact resistance, flame-retardant properties (UL94 ratings), and the incorporation of transparent windows (made from polycarbonate or glass) for viewing indicators without exposing live parts. The design must ensure that once installed, it prevents access to hazardous voltages without the use of a tool, a principle known as "tool-safe" design. Gaskets are frequently used with these plates to achieve a degree of environmental sealing for outdoor or washdown panels.

When the application demands exceptional strength, corrosion resistance, and a professional appearance, a stainless steel cover plate is frequently the material of choice. Grades like 304 stainless offer excellent general corrosion resistance, while 316 stainless provides superior protection against chlorides, making it ideal for marine or chemical processing environments. Stainless steel plates offer high structural integrity, can be polished or brushed for a high-end finish, and maintain their appearance under harsh conditions. They are commonly used in food and beverage equipment, medical devices, architectural fixtures, and outdoor telecommunications enclosures where durability is paramount.

| Material | Key Advantages | Typical Applications |

| Stainless Steel (304/316) | High strength, excellent corrosion resistance, hygienic, durable finish. | Food processing, marine, medical, architectural, chemical. |

| Aluminum (e.g., 6061) | Lightweight, good strength-to-weight ratio, corrosion resistant, good thermal/electrical conductivity. | Electronics enclosures, automotive parts, heat sinks, lightweight structures. |

| Cold Rolled Steel (CRS) | High strength, low cost, easily plated (zinc, nickel) for corrosion protection. | Industrial machinery, internal brackets, non-critical enclosures (when painted). |

| Engineering Plastics (PC, ABS, Nylon) | Electrical insulation, light weight, design flexibility, corrosion-proof. | Electrical enclosures, consumer products, prototypes. |

For applications exposed to moisture, rain, or even submersion, a standard cover plate is insufficient. A waterproof cover plate is a system engineered to achieve a specific Ingress Protection (IP) rating. The IP code (e.g., IP67) defines the level of sealing effectiveness against solids and liquids. Achieving a high IP rating involves multiple design elements: a robust plate material, a continuous compression gasket (made from silicone, EPDM, or neoprene) seated in a precisely machined groove, strategically placed and sealed fasteners, and sometimes, the elimination of all through-holes. The mating surfaces must be flat and smooth to allow the gasket to compress evenly, forming a complete seal. These plates are essential for outdoor electrical installations, underwater sensor housings, and washdown equipment in the food and pharmaceutical industries.

When standard, stamped, or off-the-shelf plates cannot meet the unique geometric, functional, or performance requirements of a project, the solution is a custom machined cover plate. Computer Numerical Control (CNC) machining allows for the creation of plates with complex contours, precise bore patterns for multiple connectors, integrated mounting features, tight tolerances (often within ±0.05mm), and specialized surface finishes. This process is ideal for low to medium volume production, prototypes, and applications where the cover plate must interface perfectly with other custom components. It enables the integration of features like heat dissipation fins, recessed areas for labels or displays, and intricate branding details that are impossible with standard forming processes.

Successfully specifying and procuring a cover plate requires navigating technical standards and providing clear, comprehensive information to manufacturers.

For many applications, adhering to established cover plate dimensions standard is crucial for interchangeability, safety, and compliance. In electrical engineering, standard DIN or ANSI flange sizes dictate the dimensions and bolt patterns for panel cutouts. In construction, switch and outlet cover plates follow standard sizing for compatibility with electrical boxes. When providing specifications, key dimensions to define include the overall length, width, and thickness; the size and location of the opening it must cover; the diameter, location, and thread specification of all mounting holes; and any critical tolerances on these dimensions. Providing a detailed dimensional drawing is the most effective way to communicate requirements and avoid errors in manufacturing.

Selecting the optimal cover plate involves balancing performance, cost, and manufacturability. Start by clearly defining the non-negotiable requirements: the environmental conditions (IP rating, chemical exposure, temperature range), mechanical loads, regulatory certifications needed, and the required quantity. With these constraints in place, evaluate material and process options. For high-volume production of simple shapes, stamping or cold extrusion may be most cost-effective. For complex, low-volume, or high-precision parts, CNC machining is appropriate. Always request prototypes or first-article inspections for custom parts to validate fit, form, and function before full-scale production.

| Selection Factor | Questions to Ask | Impact on Choice |

| Environment | Indoor/outdoor? Exposure to moisture, chemicals, UV? Temperature extremes? | Dictates material (stainless vs. aluminum) and need for sealing (gaskets, IP rating). |

| Function | Is it structural? Does it need to dissipate heat? Shield EMI? Provide optical clarity? | Influences material thickness, choice of metal vs. plastic, and need for coatings or finishes. |

| Quantity & Lead Time | Prototype, low-volume, or high-volume production? What is the project timeline? | Determines the most economical manufacturing process (CNC machining vs. stamping vs. casting). |

| Budget | What is the target cost per part? | Balances material cost (e.g., 316 vs. 304 SS) with manufacturing process cost. |

Both serve to close off an opening, but their context and design differ. A cover plate is a general term for a plate used to close an access opening on a housing, enclosure, or machine. It is typically fastened with multiple screws or clips around its perimeter. A blind flange is a specific type of cover plate used in piping systems. It is designed to mate with a standard pipe flange (using a matching bolt circle and gasket) to permanently or temporarily seal the end of a pipe. While a blind flange is a cover plate, not all cover plates are flanges; flanges are defined by their standardized method of connection to pipes or vessels.

Selecting material for corrosion resistance requires identifying the specific corrosive agents. For general atmospheric or mild chemical exposure, aluminum with an anodized finish or 304 stainless steel may suffice. For exposure to chlorides (seawater, de-icing salts) or strong acids/alkalis, 316 stainless steel is a significant upgrade. For highly aggressive chemical environments, more exotic alloys like Hastelloy, titanium, or specialized plastics (PVDF, PTFE) may be necessary. Consulting a corrosion resistance chart for your specific chemical and considering temperature is essential. When in doubt, a stainless steel cover plate in grade 316 is a robust, widely available choice for demanding environments.

IP (Ingress Protection) rating is an international standard (IEC 60529) that classifies the degree of protection provided by an enclosure against solids and liquids. It is expressed as "IP" followed by two digits. The first digit (0-6) indicates protection against solid particles (6 being dust-tight). The second digit (0-9K) indicates protection against liquids, with common ratings being 5 (water jets), 6 (powerful water jets), 7 (temporary immersion up to 1m), and 8 (prolonged immersion under pressure). Therefore, a waterproof cover plate rated IP67 is completely dust-tight and can be immersed in water up to 1 meter deep for 30 minutes without ingress.

Consider a custom machined cover plate when: 1) Standard plates do not fit your unique dimensional or mounting requirements. 2) You need to integrate multiple functions into a single part (e.g., mounting bosses, recessed areas). 3) Your application requires extremely tight tolerances for proper sealing or component alignment. 4) You are working with a low to medium production volume where the cost of custom tooling for stamping or casting is prohibitive. 5) You need to use a specific material that is not available in standard plate forms or requires precision machining to achieve desired properties.

To ensure a cover plate is manufactured correctly, you should provide a detailed drawing or clearly specify: 1) Overall dimensions (Length, Width, Thickness). 2) The size and location of the primary opening it must cover. 3) The diameter, location (from datum edges), and depth of all mounting holes, along with thread specifications (e.g., M4 through-hole, M6 tapped hole 10mm deep). 4) Any critical positional tolerances for these holes. 5) Radius or chamfer specifications for corners. Providing this information in a standardized format avoids ambiguity and ensures the final part matches your cover plate dimensions standard or custom requirements.