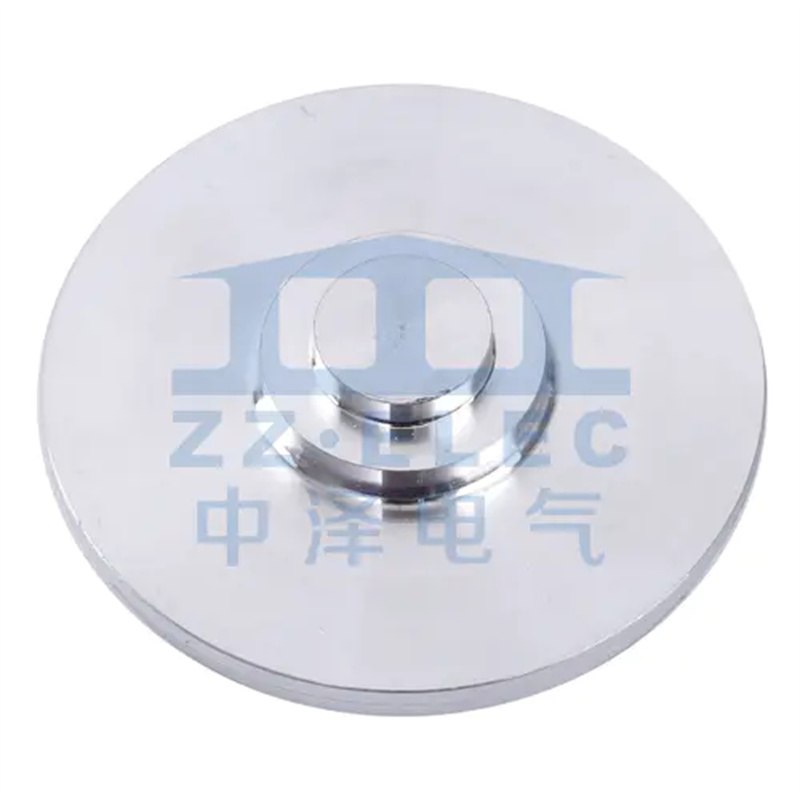

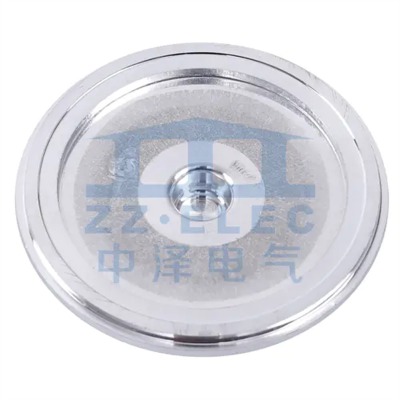

Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

Selecting the optimal cover plate for your kitchen or bathroom is a critical decision that bridges aesthetics, engineering, and long-term functionality. Often overlooked as a mere finishing piece, a cover plate serves as a vital sealant, a structural supporter, and a defining design element. This guide provides a professional, in-depth analysis to help homeowners, contractors, and procurement specialists make an informed choice, covering everything from material science and precise measurement to installation protocols and stylistic integration.

Beyond its visible role, a cover plate is a multi-functional component engineered to solve specific problems. Its primary function is to create a watertight and airtight seal between the sink or faucet and the countertop substrate. This prevents moisture, debris, and bacteria from infiltrating the vulnerable cut-out edges, which is crucial for preventing countertop swelling, mold growth, and laminate delamination. Secondly, it provides critical mechanical support, especially for heavy under-mount sinks or brittle countertop materials like quartz or porcelain slabs, distributing the load and preventing stress cracks from radiating out from the cutout. Finally, it conceals imperfections in the cut-out and the gap between the fixture and the countertop, ensuring a clean, finished appearance. The choice of material directly dictates how well it performs these functions, balancing properties like corrosion resistance, malleability for sealing, and structural strength.

The performance of a cover plate is intrinsically linked to the properties of its base material. Each option offers a distinct balance of strength, corrosion resistance, workability, and cost. Understanding these properties at a fundamental level allows for a selection that matches the specific environmental demands and load requirements of the application.

| Material | Key Engineering Properties | Ideal Application & Notes |

| Stainless Steel | High tensile strength, excellent stainless steel cover plate corrosion resistance (especially Grade 304), hygienic, malleable for forming. | Universal use; superior for kitchens and high-moisture areas. Polished or brushed finishes affect cleanability and scratch visibility. |

| Brass | Good machinability, natural antimicrobial properties, develops a patina over time unless lacquered. | Often used for decorative faucet escutcheons; heavier and more expensive than steel. |

| Zinc Alloy (Zamak) | Excellent for intricate die-casting, good surface for plating (chrome, nickel), cost-effective. | Common for complex decorative cover plate designs for bathrooms; corrosion resistance depends entirely on plating quality and integrity. |

| Solid Surface/Quartz | Seamless visual integration with the countertop, moderate strength, repairable. | Used when an invisible or perfectly matched look is desired; fabricated by countertop professionals. |

The journey to the perfect cover plate begins with precision and ends with a specification that meets all functional and aesthetic criteria. Two of the most critical and often error-prone steps are obtaining accurate measurements and selecting the appropriate material and thickness. These steps are interdependent; an incorrectly measured plate, even in the best material, will fail to seal properly, while a perfectly sized plate in an unsuitable material will not endure.

Accuracy in how to measure for a replacement cover plate is non-negotiable. An error of even a few millimeters can result in an ineffective seal, visible gaps, or an inability to install the fixture. The process requires careful attention to the geometry of the existing cutout and the fixture it must accommodate.

For manufacturers like Zhejiang ZZ Electric Co., Ltd., precision is ingrained in their process. While specializing in cold extrusion technology for aluminum automotive and battery components, their expertise in high-tolerance manufacturing—utilizing advanced German HERLAN extrusion equipment and CNC machining—translates to a deep understanding of dimensional accuracy. This level of precision is equally critical when producing or specifying engineered components like cover plates, where consistent dimensions ensure perfect fit and function.

The specification of a cover plate involves quantifiable metrics that guarantee performance. Cover plate thickness for countertop support is the primary structural metric. For a standard stainless steel sink cover plate supporting an under-mount sink, a thickness of 1.2mm (18 gauge) is typically considered a minimum for adequate rigidity. For heavier stone sinks or in commercial applications, 1.5mm (16 gauge) or thicker is recommended to prevent flexing. The material grade is equally crucial; for stainless steel cover plate corrosion resistance, Type 304 stainless steel is the industry standard for damp environments, offering superior protection against rust and pitting compared to Type 430 or 201.

Once the technical specifications are locked in, the cover plate becomes a canvas for design. Its finish, profile, and detail can either subtly complement or boldly accent the space. Successful integration requires a thoughtful approach to style, followed by a meticulous installation that ensures the plate's performance matches its promise.

Cover plates have evolved from purely functional items to key decorative elements. In bathrooms, decorative cover plate designs for bathrooms can transform a simple faucet into a focal point. Options include intricate laser-cut patterns, hammered textures, brushed or polished finishes in various metals, and even custom-colored plates to match bathroom hardware. The edge profile—beveled, ogee, or flat—also contributes significantly to the visual weight and style. The goal is to create a cohesive look that ties together all metallic finishes in the room, from towel bars to lighting.

A flawless kitchen sink cover plate installation is a systematic process that guarantees longevity. Skipping steps or using inferior sealants is a common cause of failure.

While possible, it is generally not recommended for plates in high-wear, wet areas. Standard spray paints lack the adhesion and chemical resistance needed for sinks and counters. They will quickly chip and peel. For a permanent color change, professional electroplating or powder coating is required. For a temporary solution, specially formulated appliance epoxy paints offer better durability, but surface preparation (sanding, degreasing) is absolutely critical, and the finish will still be less durable than an original factory coating.

A sturdy cover plate can act as a structural reinforcement clamp, helping to stabilize and prevent the propagation of a minor, non-structural hairline crack once it has been professionally repaired with epoxy resin. However, it is not a solution for a significant crack that compromises the countertop's integrity. The proper procedure is: 1) Have the crack professionally repaired and epoxy-injected by a stone fabricator. 2) Once repaired, a heavy-gauge plate installed with a strong adhesive sealant can be used to bridge and reinforce the area, distributing future loads away from the crack. Always address the structural repair first.

There is no universal standard, which makes accurate measurement essential. The most common configurations for widespread faucets (separate hot and cold handles) are center-sets of 4 inches or 8 inches. However, single-hole, 3-hole (4-inch or 8-inch spread), and wall-mounted plates all have different requirements. The key is to match the plate to your specific faucet model's footprint and hole layout. Always refer to the faucet manufacturer's specification sheet for the required or recommended escutcheon dimensions.

Effective removal requires a combination of mechanical and chemical methods. First, use a sharp plastic or metal putty knife to scrape away the bulk of the sealant. For the tenacious residue, apply a commercial silicone sealant remover gel, allowing it to dwell and soften the material as per the product's instructions. Avoid harsh razor blades on delicate surfaces like polished granite or soft metals, as they can cause scratches. For stainless steel plates, a gentle scrubbing with a non-abrasive pad after chemical treatment is effective.

These are often confused but serve different primary functions. A sink rim (or "clip-on" rim) is typically part of a top-mount (drop-in) sink. Its main job is to rest on the countertop, providing a lip that holds the sink in place from above, with sealant applied underneath. A cover plate is primarily used with under-mount or flush-mount installations. It is installed on top of the countertop, with its purpose being to cover and seal the gap between the sink's upper edge and the countertop material. The cover plate is a separate component focused on sealing and aesthetics, while the sink rim is an integral part of the sink's mounting system.