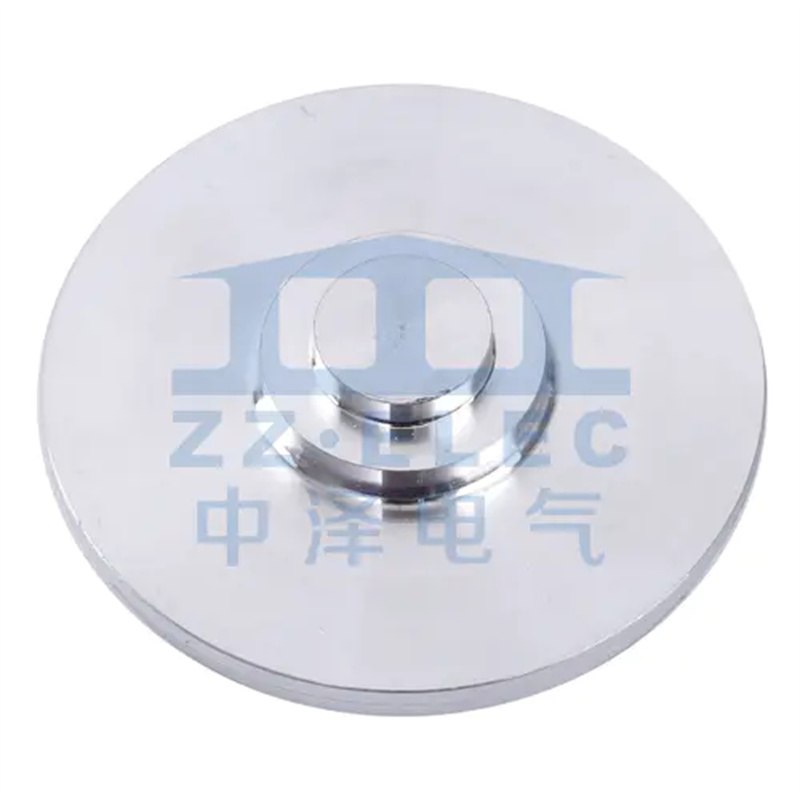

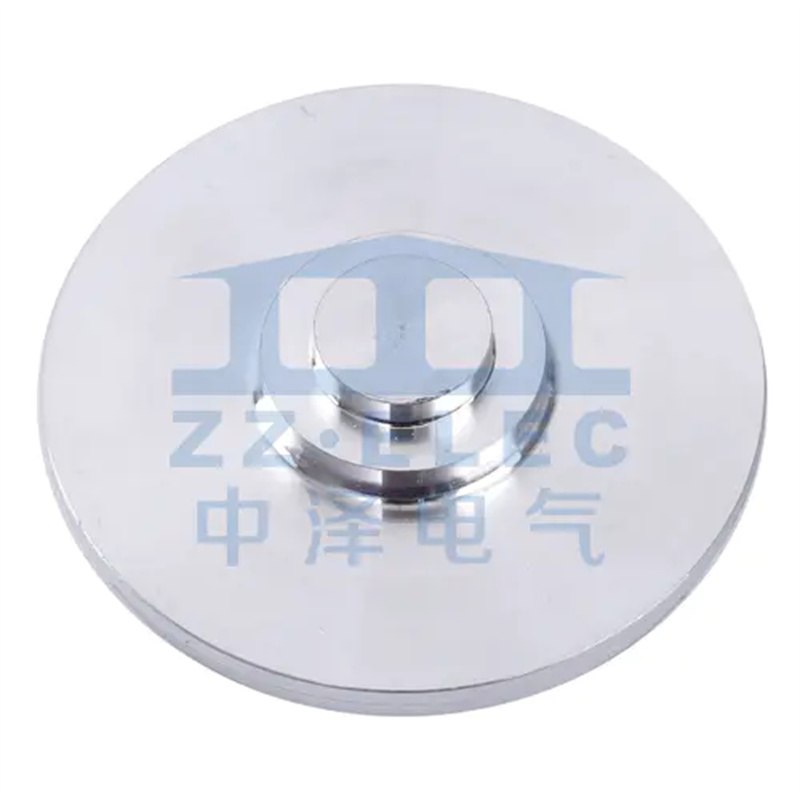

Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

In the intricate world of industrial design, machinery, and construction, some components play starring roles, while others provide critical, albeit less visible, support. The cover plate firmly belongs to the latter category. Often perceived as a simple lid or cap, a cover plate is, in fact, a fundamental engineering element whose proper selection and implementation are vital for system integrity, safety, and longevity. Its primary functions extend far beyond mere enclosure, serving as a seal against contaminants, a barrier for safety, a contributor to structural rigidity, and a point of access for maintenance. From the massive housing of industrial pumps to the delicate enclosure of an electronic sensor, the humble cover plate is ubiquitous. This article delves into the engineering considerations, material science, and application-specific designs that define a high-quality cover plate, helping engineers, procurement specialists, and maintenance managers make informed decisions. We will explore key variants, including the heavy duty steel cover plate, the precision custom machined aluminum cover plate, and the specialized waterproof electrical junction box cover plate, providing a comprehensive guide to understanding when and why you need a specific type of cover plate for your application.

A cover plate is a manufactured part designed to close an opening in a machine, enclosure, or structure. Its engineering purpose is multifaceted and critical to operational success. At its most basic, it provides a protective barrier, but its roles are significantly more complex and interdependent. Firstly, it acts as a seal, preventing the ingress of external contaminants such as dust, dirt, moisture, and corrosive chemicals, while also potentially containing internal fluids or gases. This protective function is directly tied to safety, as a robust cover plate serves as a physical guard, isolating personnel from moving parts, electrical contacts, or high-temperature surfaces. Furthermore, when securely fastened, a cover plate can contribute to the overall structural stiffness of an assembly, reducing flex and vibration in panels or housings. Finally, it offers a finished appearance and, when designed with hinges or quick-release fasteners, provides convenient access for inspection, adjustment, or repair. Neglecting the specification of a correctly designed cover plate can lead to catastrophic failures, including premature wear of internal components, electrical shorts, safety hazards, and unplanned downtime, making its selection a key engineering consideration rather than an afterthought.

The performance of a cover plate is intrinsically linked to its material composition. The choice of material dictates its strength, weight, corrosion resistance, manufacturability, and cost. Selecting the wrong material can lead to rapid degradation, seal failure, or structural inadequacy. For instance, a plate meant for an outdoor electrical application requires excellent corrosion resistance and weatherability, while one for a high-pressure hydraulic system demands immense tensile strength. Engineers must balance these functional requirements against factors like budget and weight constraints. The manufacturing process—whether it's machining, stamping, casting, or injection molding—is also determined by the chosen material and the required geometric complexity. Understanding the core material groups is the first step in specifying the correct component.

Specifying a cover plate requires a systematic analysis of the operational environment and performance requirements. It is not a one-size-fits-all component. The design process begins with a clear understanding of the loads it must withstand—be it static pressure from contained fluids, dynamic冲击 loads from impacts, or cyclic thermal stresses. The environmental conditions, such as exposure to UV radiation, salt spray, or industrial chemicals, will heavily influence material and coating selection. Furthermore, the sealing strategy is critical; whether using a simple gasket, a molded O-ring in a dedicated groove, or a form-in-place sealant, the interface must be designed to maintain integrity over the product's lifespan. Fastening method is another key consideration, with choices ranging from permanent welding or bonding to removable screws, latches, or cam locks for frequent access.

| Design Factor | Key Questions | Common Solutions & Examples |

| Load & Environment | What pressure, shock, or thermal cycles will it face? Is it exposed to chemicals or weather? | Finite Element Analysis (FEA) for stress points. A cover plate for pump housing must be designed for internal pressure and vibration. |

| Sealing Mechanism | What level of sealing (dust-tight, watertight, pressure-tight) is required? | Gaskets (rubber, cork), O-rings, lip seals, or silicone bead sealing. Choice depends on media and pressure. |

| Fastening & Access | How often does it need to be opened? What tools are available? | Socket head cap screws for permanence, quarter-turn fasteners for tool-less access, or hinges for swing-open designs. |

| Compliance & Standards | Are there industry-specific safety or performance standards? | A waterproof electrical junction box cover plate must meet IP (Ingress Protection) ratings like IP65 or IP67, verified by standardized testing. |

The theoretical design principles of cover plates come to life in their diverse industry applications. Each sector presents unique challenges that dictate specific solutions. In heavy industry, the focus is on durability and containment under extreme conditions. In contrast, the electrical industry prioritizes safety, insulation, and environmental sealing. The evolution of custom manufacturing and advanced materials has also opened doors for highly specialized applications in technology and precision engineering. By examining these use cases, we can see how the generic concept of a cover plate is refined into critical, application-specific components.

Both IP (Ingress Protection) ratings relate to a waterproof electrical junction box cover plate, but they define different levels of protection. The first digit (6 in both cases) indicates complete protection against dust ingress. The second digit defines protection against water. An IP65 rating means the cover plate is protected against "low-pressure water jets" from any direction. An IP67 rating is more stringent, indicating the enclosure can withstand "immersion in water" between 15cm and 1m depth for a limited time (typically 30 minutes). Choosing between them depends on whether the installation faces occasional hose-downs (IP65) or potential temporary flooding (IP67).

The choice hinges on your priority: ultimate strength or weight reduction. A heavy duty steel cover plate is the default for applications requiring maximum impact resistance, durability in abrasive environments, or where magnetic properties are needed. It is typically less expensive in terms of material cost but heavier. An aluminum plate is preferable when reducing weight is critical to improve portability or reduce load on supporting structures, or when good corrosion resistance without painting is desired. For complex shapes, a custom machined aluminum cover plate might be easier and more cost-effective to produce in prototype or low-volume runs.

A plastic injection molded cover plate offers several distinct advantages for high-volume manufacturing. First, it allows for extreme design complexity, integrating features like living hinges, snap-fits, mounting bosses, and aesthetic textures directly into the part in a single molding cycle. Second, the per-unit cost becomes very low at high quantities. Third, plastic provides excellent electrical insulation and resistance to a wide range of chemicals. Finally, it is lightweight and can be produced in various colors without secondary painting. The trade-offs are generally lower maximum service temperature and strength compared to metal equivalents.

You need a custom machined aluminum cover plate (or one from another material) when standard parts cannot meet your specific requirements. This includes unique dimensional constraints, non-standard hole patterns for mounting proprietary components, the need for precise tolerances to ensure sealing or alignment, or the incorporation of special features like channels, recesses, or engraved markings. Custom machining is ideal for prototypes, pilot runs, and specialized equipment where the design is not yet finalized for mass production tooling like injection molding.

A leaking cover plate for pump housing is a serious issue that can lead to performance loss and environmental/safety hazards. A systematic check should include: 1) Fastener Torque: Ensure all bolts are tightened to the manufacturer's specified torque in the correct sequence (criss-cross pattern). 2) Gasket/Condition: Inspect the seal (gasket or O-ring) for wear, compression set, chemical degradation, or cuts. It is often the primary culprit and should be replaced with the correct material for the fluid. 3) Sealing Surfaces: Check both the cover plate and the mating housing surface for warping, pitting, scratches, or corrosion that could prevent a tight seal. 4) Thermal Expansion: Consider if recent thermal cycling has affected the seal's integrity.