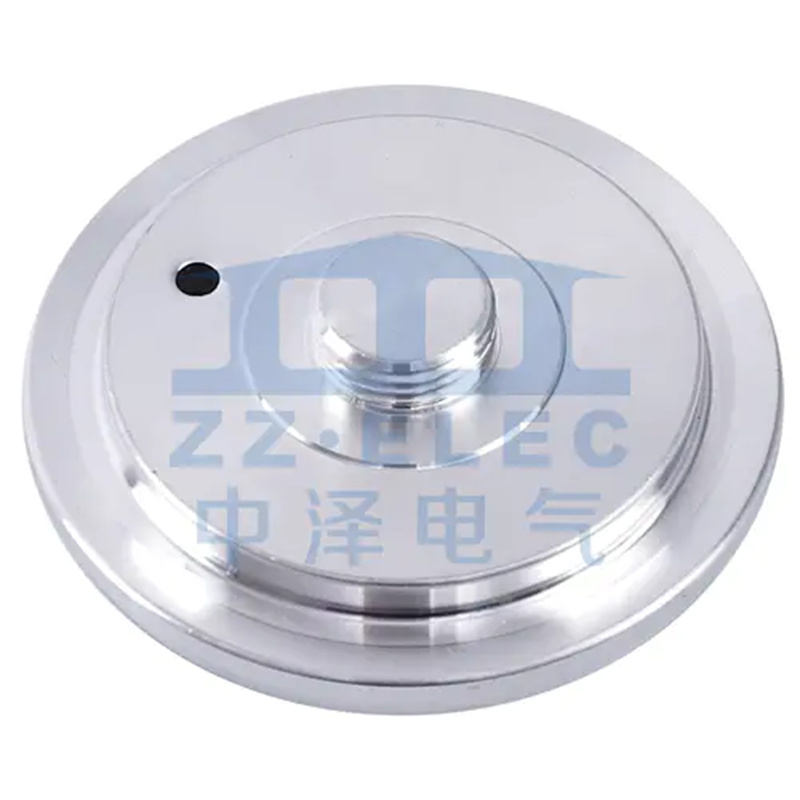

Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

The humble cover plate, often treated as a mere aesthetic finishing touch, plays a profoundly critical, multifaceted role in any electrical system. These seemingly simple fixtures are, in essence, the final barrier between live electrical components and the external environment, and by extension, human interaction. A truly durable cover plate functions as an indispensable protective shell, shielding wiring, switches, and receptacles from dust, moisture, and potential physical damage. Ignoring the need for resilience here is a significant oversight, as a flimsy or damaged plate can compromise the entire integrity of the electrical installation, creating both a functional hazard and a maintenance liability. Investing in robust solutions like heavy-duty electrical switch plate covers means prioritizing sustained safety and operational longevity over short-term cost savings, directly impacting the long-term reliability of the infrastructure.

The secret to enduring performance lies in the science of the material and the precision of the manufacturing process. Durability is not a coincidence; it is a deliberate design choice that focuses on preventing common failure points.

The foundational choice of material dictates a cover plate's resistance to various stresses. While standard thermoplastic serves basic needs, environments demanding true resilience call for superior compounds. For specialized outdoor applications, materials like high-grade polycarbonate or certain composite blends are essential to craft weather-resistant outdoor receptacle covers. These materials are specifically formulated to withstand prolonged exposure to ultraviolet radiation, extreme temperature fluctuations, and moisture ingress without becoming brittle, cracking, or discoloring. For high-traffic or industrial areas, heavy-gauge metal alloys or advanced thermoset plastics offer the requisite structural strength to resist high kinetic impact and abrasions, a crucial factor when considering the long-term integrity of the installation. A proper material selection is the cornerstone of avoiding premature failure and the resulting need for frequent, costly replacements.

Structural integrity extends beyond material composition to encompass the design itself. Plates intended for challenging locations, particularly where physical damage is probable, should demonstrate an exceptional capability for impact dispersion. This is the domain of impact-resistant wall plate material comparison, where factors such as thickness, flexibility, and corner design are rigorously tested. Furthermore, for installations exposed to the elements, effective sealing mechanisms and precise fitting are non-negotiable. The engineering must ensure a tight seal against the mounting surface, preventing the seepage of rain or humidity that could lead to corrosion or short circuits. This comprehensive approach to design ensures that the cover plate remains a reliable shield against both accidental force and environmental degradation.

The necessary degree of cover plate durability is not uniform; it must be calibrated to the specific demands and stresses of its operational environment.

In commercial kitchens, workshops, hospitals, or manufacturing plants, electrical fittings are subjected to intense wear, frequent cleaning, and potential chemical exposure. Here, the focus shifts to robust, long-lasting metal faceplates for commercial use, often made from stainless steel or brass, which can withstand aggressive cleaning agents and provide superior resistance to physical abuse from heavy machinery or tools. Durability in these settings translates directly to reduced downtime and compliance with rigorous safety regulations. The ability to endure constant use without failing is a fundamental operational requirement, positioning the cover plate as a critical piece of operational equipment, not just an accessory.

Even in a seemingly benign residential setting, durability adds significant long-term value. Areas like garages, workshops, or children’s play areas often experience accidental bumps or misdirected impacts. Choosing unbreakable light switch plates for these zones mitigates the risk of shards or exposed wiring that can result from a simple breakage. The minimal initial extra cost of a more durable plate is quickly offset by avoiding the need for future replacements and maintaining a consistently safe and polished appearance over decades, making the choice a sensible and frugal long-term decision for the homeowner.

The primary objective of a durable cover plate is the sustained protection of the electrical system, a function that is inextricably linked to user safety. A cracked, warped, or loose plate can expose internal wiring or provide a pathway for conductive material to enter the enclosure. This is where the plate's structural integrity becomes a life-saving feature. By consistently maintaining its intended form and fit, the plate ensures that the insulation barrier remains complete and effective. How to choose unbreakable light switch plates often involves selecting designs that fully enclose and recess all mounting screws and edges, eliminating potential snag points and ensuring a smooth, continuous surface. This robust physical barrier is the silent sentinel against arc faults, shocks, and electrical fires, ensuring that the critical safety function of the electrical box remains uncompromised throughout its operational life.

The true economy of a durable cover plate is realized over the extended lifespan of the installation. Plates made from resilient, high-quality materials drastically lengthen the time between necessary replacements. A less robust plate, prone to cracking, discoloration, or warping from environmental stressors, necessitates frequent labor-intensive maintenance and replacement, incurring significant costs over time. Conversely, the initial, slightly higher expenditure on an exceptionally sturdy plate results in a far lower total cost of ownership (TCO). This reduction in maintenance frequency is a powerful long-term benefit, allowing resources to be allocated elsewhere. Long-lasting metal faceplates for commercial use, for example, require only minimal periodic cleaning, offering a virtually set-and-forget solution that maintains a professional appearance and full safety functionality for years, confirming that durability is not a luxury, but a core component of sustainable, cost-effective infrastructure management.