Fuel Filter Structure

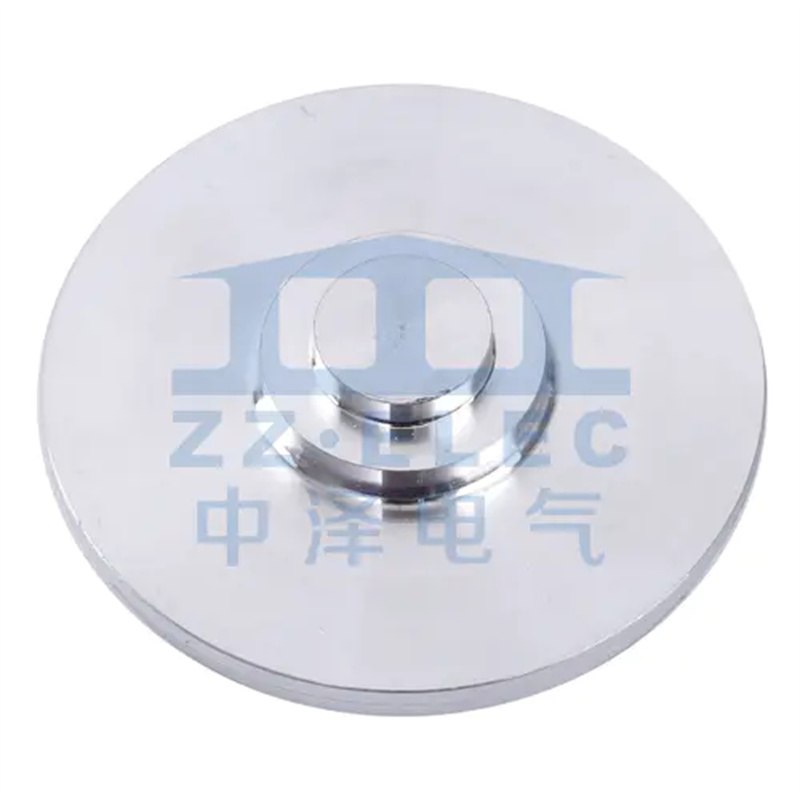

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

In modern industrial and architectural contexts, cover plates serve not only protective roles but also aesthetic ones, especially for equipment, electrical enclosures, and wall cutouts. Given the wide range of material options, machining tolerances, environmental durability requirements, and appearance details, selecting a specialized, reliable cover plate manufacturer is crucial. Many projects now demand customization rather than standard sizes, materials, or colors. Especially in high-end residential settings, smart home systems, industrial automation enclosures, control panel facades, and decorative wall plates, clients emphasize unique design and precise fit. Thus, manufacturers capable of “custom cover plate manufacturers in China” exhibit competitive advantage. As downstream demand shifts from large standardized orders toward diverse, small-batch, design-variant products, customization ability becomes a key differentiator.

When selecting a factory, “location” and “material” are among the first considerations. China, with its mature metal and plastic processing supply chains, offers complete upstream and downstream support, making it attractive for those seeking cost-effective, reliably delivered suppliers. If your requirement is “stainless steel cover plate manufacturers for switchgear,” you must confirm whether your supplier has stainless steel procurement channels, bending and welding capabilities, surface treatments (brushing, sandblasting, plating), and experience controlling assembly tolerances appropriate for switchgear. Conversely, for wall decoration or home style cover plates requiring patterning, coating, or mirror/brush finishes, one must examine the maturity of the supplier’s craft and consistency in aesthetics across batches.

In industrial, electronics, or control cabinet applications, cover plates must satisfy not only aesthetics but also electromagnetic compatibility, heat dissipation, insulation, dust- and water-resistance, and mechanical strength. If you search for “industrial cover plate manufacturer for electrical enclosures,” focus on factories’ technical capabilities: laser cutting, CNC bending, surface spray or powder coating, gasket groove design, precise threaded hole positioning, and durability testing (salt spray, temperature/humidity cycling, impact). Only manufacturers with solid functional and structural performance can maintain stable performance and long life in prolonged use.

Pricing is always important. But focusing solely on low price may bury quality risks. You might screen with “low cost cover plate manufacturers for OEM” but when cooperating, you must validate via sample testing, third-party inspections, and factory audits. You should evaluate incoming inspection, in-process inspection, final product sampling, protective packaging design, shipment acceptance standards, and defect return/repair policies. High quality manufacturers typically provide test reports, process records, PPAP or sample test data, ensuring that low cost does not come at the expense of quality.

As an OEM client, you want suppliers to balance cost, lead time, and quality. In early cooperation, adopt small trial orders, sample validation, stage inspections, and contract quality or penalty clauses to mitigate risk. You may specify use cases such as “decorative cover plate manufacturers for walls,” requiring that suppliers satisfy functional demands but also aesthetic consistency and process stability. Over long-term collaboration, share order forecasts, technical specs, and volumes to encourage manufacturers to optimize processes, lower unit cost, and mature craftsmanship. The ultimate goal is to achieve “low cost + high quality + stable delivery” and to build a sustainable, win-win supply chain.

=