Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

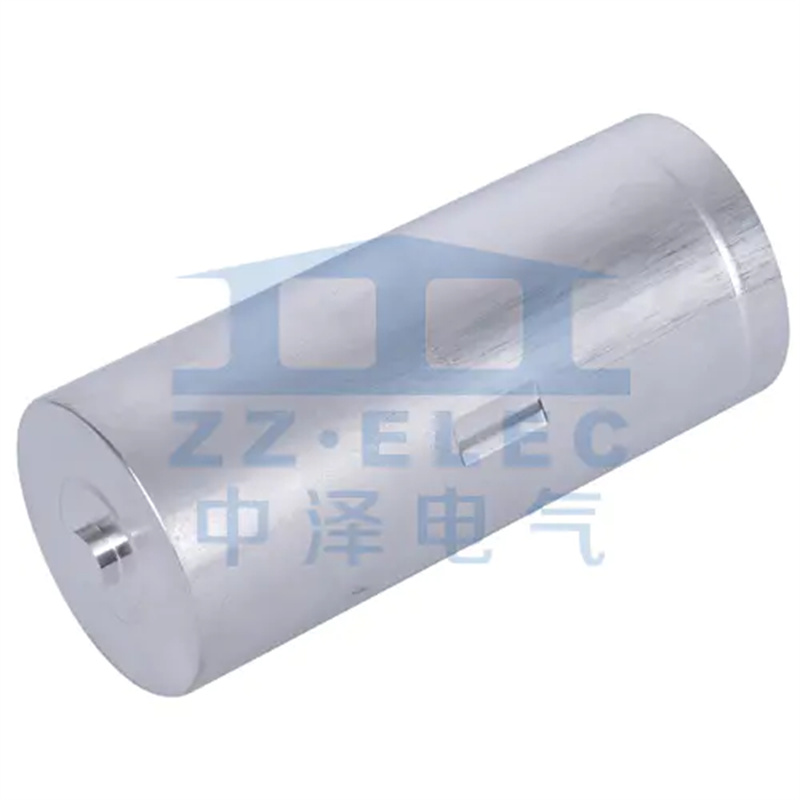

In today’s era of rapid development in new energy technologies, supercapacitors—highly efficient energy storage devices—are playing an increasingly vital role. With their ultra-high power density, rapid charge-discharge capabilities, and long cycle life, they demonstrate enormous application potential in fields such as electric vehicle acceleration, instantaneous high-power output in industrial equipment, and peak-valley regulation in grid energy storage. However, these powerful performances do not emerge in a vacuum. Beyond their intricate internal electrochemical structures, a robust, functionally comprehensive cylindrical casing is equally crucial. This “coat” is more than a simple physical barrier; it is the key to ensuring the supercapacitor’s stable performance, safety, and reliability.

Generic casing designs often struggle to meet the specific needs of diverse applications—such as pressure resistance in high-vibration environments, heat dissipation efficiency under extreme temperatures, or corrosion resistance against specific chemicals. Thus, tailoring exclusive cylindrical casings for supercapacitors has become an inevitable choice to enhance their overall performance and safety.

Customizing a cylindrical casing for supercapacitors begins with material selection. Traditional aluminum casings are widely used for their excellent conductivity and lightweight properties, but scenarios demanding higher corrosion resistance or strength call for stainless steel or even composite materials. The choice of material directly impacts the capacitor’s weight, heat dissipation, and compatibility with internal electrolytes—ultimately influencing its power density and cycle life.

For example, in electric vehicles where extreme lightweighting is critical, casings made of high-strength aluminum alloys or specialized composites can reduce overall vehicle weight while ensuring safety, thereby extending range. Structural design also poses challenges: casing thickness, sealing methods, and internal support structures must be precisely calculated based on the capacitor’s capacity, operating voltage, and intended environment. A well-designed structure not only resists external physical impacts but also optimizes internal heat conduction paths, ensuring heat generated during high-power charge-discharge cycles is dissipated promptly to prevent performance degradation or safety hazards.

The role of the casing in optimizing supercapacitor performance is far greater than imagined. High-performance custom casings, crafted through precision manufacturing, achieve superior encapsulation, minimizing internal moisture and oxygen penetration to fundamentally guarantee long-term stability and reliability.

High-precision casing designs ensure tight integration between the cell and casing, reducing internal stress and effectively extending the capacitor’s cycle life. Additionally, custom casings can integrate multiple functions—for instance, incorporating built-in structures for connectivity and heat dissipation simplifies external module integration and boosts overall system power density. A meticulously designed casing can enhance tolerance for high-power charge-discharge cycles without increasing volume—a critical advantage for applications requiring instant power, such as heavy machinery startup or grid frequency modulation. It is not merely a physical protector but an extension and safeguard of the supercapacitor’s core performance.

Designing supercapacitor casings is an art of balance, requiring the optimal blend of lightweight properties and durability. In electric vehicles, every gram saved translates to extended range, making lightweighting a core goal. Designers favor thin-walled, high-strength materials and optimize structures to eliminate unnecessary material usage.

In contrast, harsh environments like heavy machinery or industrial energy storage—where capacitors face intense vibration, impact, and temperature fluctuations—prioritize durability and pressure resistance. Thicker walls, stronger materials, and structural reinforcements become essential here. Future trends will explore innovative materials, such as graphene composites with exceptional thermal conductivity or carbon fiber materials with higher strength-to-weight ratios, which promise to revolutionize supercapacitor performance while balancing lightweighting and durability.

Safety is an uncompromising priority in supercapacitor design, and the casing—acting as both the first and last line of defense—holds immense importance. Custom casing designs must prioritize explosion-proof and sealing functionalities.

For example, casing tops typically feature pressure relief valves or burst discs. If internal pressure spikes due to abnormalities (e.g., overcharging or short circuits), these devices rapidly release pressure to prevent explosive failure, protecting surrounding equipment and personnel.Meanwhile, the sealing process between the casing and cover is critical: it must effectively block external moisture and oxygen to avoid reactions with internal electrolytes, which could degrade performance or cause failure.

Rigorous quality control and testing standards during manufacturing ensure every custom casing meets design requirements. Techniques like X-ray inspection, leak testing, and pressure resistance testing guarantee each product delivers exceptional safety performance, providing a solid foundation for supercapacitors to operate stably in harsh environments.