Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

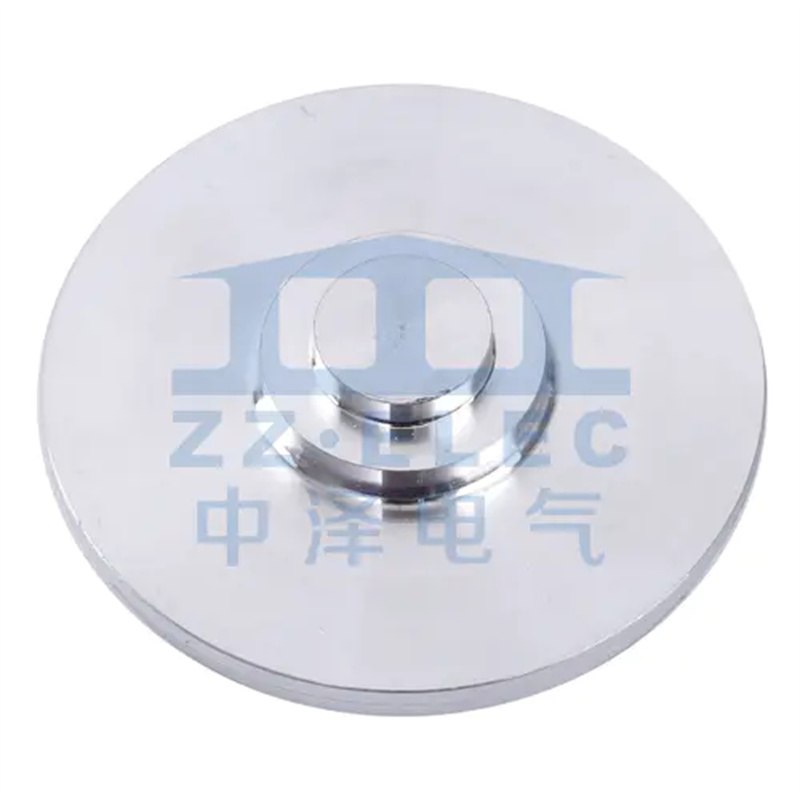

The shell of a supercapacitor is far from a simple container; it is the first line of defense ensuring the stable operation of the entire internal electrochemical system. The shell material needs to possess excellent mechanical strength to resist external impact and internal pressure, while also requiring extremely high airtightness to prevent electrolyte leakage and the intrusion of external moisture. Any minor leakage can lead to a sharp decline in performance or even failure. In terms of chemical stability, the shell must be able to withstand long-term corrosion from the electrolyte, avoiding any side reactions that could contaminate it. Furthermore, lightweight is also an important consideration, especially in fields like new energy vehicles and portable devices, where reducing weight translates to improved energy efficiency. Common material choices include various high-grade aluminum alloys, stainless steel, and specially surface-treated engineering plastics, all seeking the optimal balance between strength, weight, corrosion resistance, and cost.

The current collector is a critical component connecting the electrode active material to the external circuit, and its performance directly relates to the internal resistance and power characteristics of the supercapacitor. An ideal current collector must possess extremely high electronic conductivity to ensure current is distributed uniformly and with low loss across the entire electrode, thereby reducing energy loss during charging and discharging. The interfacial contact resistance between it and the electrode active material must be as small as possible, often requiring special surface treatments or coating processes to enhance the adhesion between the two. In terms of mechanical properties, the current collector needs sufficient flexibility and strength to cope with the volume expansion and contraction that the electrode may undergo during charge-discharge cycles. Aluminum foil is typically used for the positive electrode, while aluminum or copper foil is used for the negative electrode. Researchers are also exploring new materials like carbon-coated aluminum foil to further reduce contact resistance and improve adhesion.

The electrode is the core where supercapacitors achieve energy storage, and its microstructure fundamentally determines the device's capacitance, energy density, and power density. Current research primarily focuses on how to construct electrode materials with ultra-high specific surface area and optimized pore size distribution. A vast specific surface area provides abundant sites for charge adsorption, while a hierarchical pore structure ensures electrolyte ions can migrate quickly and smoothly. Beyond activated carbon, new carbon materials such as carbon nanotubes and graphene, due to their excellent conductivity and unique structures, can form efficient three-dimensional conductive networks, significantly enhancing rate performance. The electrode preparation process, such as slurry coating, drying, and calendering, also greatly influences the uniformity, porosity of the active material layer, and the quality of its bond with the current collector, ultimately collectively determining the overall performance of the electrode.

The separator is a porous insulating membrane placed between the positive and negative electrodes. Its core function is to physically prevent the two electrodes from directly contacting and causing an internal short circuit, while allowing electrolyte ions to pass freely. The performance parameters of the separator are crucial for the safety and reliability of the supercapacitor. Its porosity must be sufficiently high and uniformly distributed to ensure good ionic conductivity, but the pore size must be smaller than the particle size of the electrode active material to effectively block particle penetration. The separator needs excellent wettability to quickly and fully absorb the electrolyte, reducing interfacial impedance. Mechanical strength and thermal stability are equally indispensable; it must maintain shape and dimensional stability under high-temperature conditions, preventing large-area short circuits caused by shrinkage or melting, thereby avoiding serious safety issues like thermal runaway.

Assembling various independent components into a high-performance whole is the final and crucial step in the supercapacitor manufacturing process. The winding or stacking of electrodes and separators must maintain extremely high alignment accuracy.Any minor misalignment can lead to concentrated edge field strength, triggering local discharge and exacerbating self-discharge phenomena. Environmental control during assembly, such as humidity and cleanliness, must be extremely strict. Trace amounts of moisture or impurities can react with the electrolyte, generating gas and increasing internal pressure, leading to performance degradation and shortened lifespan. The final sealing step, whether by laser welding, mechanical pressing, or glue sealing, must ensure absolute airtightness while maintaining stable internal pressure, guaranteeing all components remain in their optimal operating state throughout their entire life cycle. Exquisite assembly process is the guarantee to maximize the potential of each component.