Fuel Filter Structure

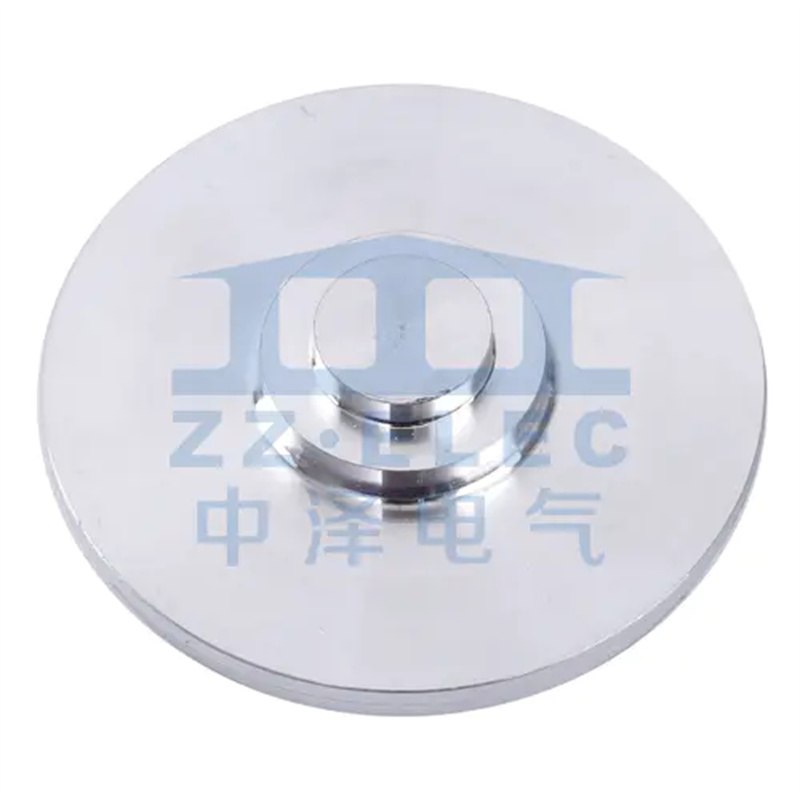

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

The rapid growth of global energy demand is forcing industries, researchers, and policymakers to search for efficient and reliable energy storage technologies. Traditional batteries have long been the dominant choice, but they suffer from limited lifespans, slow charging, and safety issues. This is where supercapacitors come in as an alternative solution.

At the very heart of their performance lies the design and engineering of Supercapacitor Structure Components. These components determine everything from cycle life to energy density, charging speed, and long-term reliability. Without a proper understanding of Supercapacitor Structure Components, it is impossible to appreciate the true potential of this technology.

So, could it be that the real revolution in energy storage is not about creating brand-new devices, but about refining and optimizing the Supercapacitor Structure Components that already exist?

Energy storage devices are not all the same. To see why supercapacitors are different, it is useful to compare them with batteries and conventional capacitors.

| Feature | Conventional Capacitors | Batteries | Supercapacitors |

| Energy Density | Very low | High | Moderate |

| Power Density | Extremely high | Low to moderate | Very high |

| Charge/Discharge Speed | Microseconds to seconds | Hours | Seconds to minutes |

| Cycle Life | Millions of cycles | Few thousand cycles | Up to millions of cycles |

| Storage Mechanism | Electric field | Chemical reaction | Electric double layer & surface redox |

From this comparison, it is clear that supercapacitors balance the strengths of both. Their unique architecture, built from specialized Supercapacitor Structure Components, allows them to act like a bridge between capacitors and batteries.

The performance of every supercapacitor depends directly on its Supercapacitor Structure Components. Let’s break them down:

The electrodes form the backbone of the device. Their surface area determines how many ions can be stored. Materials such as activated carbon are common due to their high porosity, while graphene and carbon nanotubes are being explored to push performance further. When optimized, these electrodes enhance both capacitance and conductivity.

The electrolyte allows ions to move between electrodes. It directly affects the safe voltage range, stability, and even operating temperature.

This thin, porous membrane ensures electrodes do not short-circuit while still allowing ion flow. Though simple in design, it is a critical Supercapacitor Structure Component for safe operation.

Metallic foils act as pathways for electrons, connecting electrodes to external circuits. Aluminum is a popular choice due to its conductivity and stability.

The outer casing, usually aluminum-based, ensures durability and safety. Proper sealing also prevents electrolyte leakage and extends device longevity.

Different supercapacitors exist because their Supercapacitor Structure Components vary in material choice and charge storage mechanism.

Rely entirely on electrostatic charge separation. No chemical reactions occur, making them highly reversible with long cycle lives.

Use rapid and reversible surface redox reactions. Their electrodes are often made of metal oxides or conductive polymers, allowing higher energy density.

Combine EDLC and pseudocapacitor features. They use one electrostatic electrode and one pseudocapacitive electrode, balancing both high power and higher energy density.

The way energy is stored and released is largely determined by Supercapacitor Structure Components.

Key factors influenced by structure components include:

This means every improvement in Supercapacitor Structure Components translates directly into better performance in real-world applications.

Evaluating supercapacitors requires understanding their metrics, which are closely linked to Supercapacitor Structure Components.

| Parameter | Significance |

| Capacitance | Depends on electrode surface area and porosity |

| Voltage Rating | Determined by electrolyte stability |

| Current Rating | Limited by current collectors and electrode conductivity |

| Power Density | Directly linked to ESR and structural design |

| Energy Density | Improved through advanced electrode and electrolyte design |

| Cycle Life | Dependent on durability of all structural components |

| Operating Temperature | Defined by electrolyte and packaging materials |

The next wave of supercapacitor development focuses heavily on refining Supercapacitor Structure Components.

These developments will narrow the gap with batteries and expand adoption across industries.

Supercapacitors are not just another energy storage option. Their real value lies in the precision design of Supercapacitor Structure Components—electrodes, electrolytes, separators, and packaging. These components together create devices capable of millions of cycles, rapid charging, and safe operation.

Although energy density remains a challenge, ongoing research into advanced structure components is pushing supercapacitors closer to widespread adoption. From electric transportation to renewable integration, the future of energy storage may very well depend on how we optimize and innovate around Supercapacitor Structure Components.

So, the real question is: Are Supercapacitor Structure Components the hidden innovation that could redefine global energy storage?