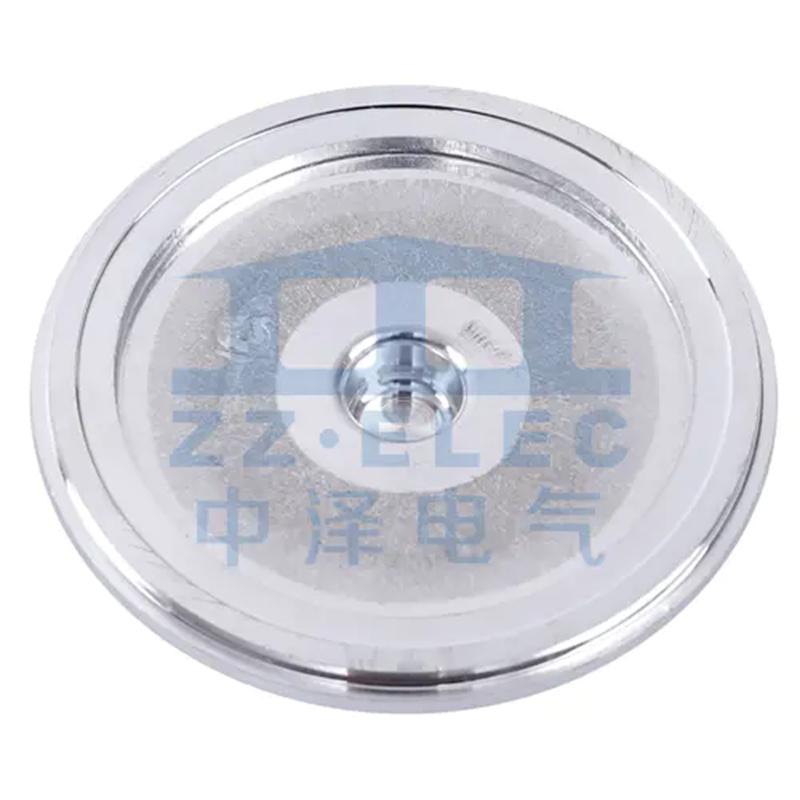

Fuel Filter Structure

Fuel filter cover&housingType: nearly every existingMaterial: AL1060We specialize in Aluminum cold extrusion. Fuel filter cover and housing could ...

In the vast landscape of modern industrial manufacturing, covers play a pivotal role as multi-functional components—protecting internal parts, ensuring sealing, and providing structural support. Among numerous materials, AL6061 aluminum alloy stands out for its exceptional comprehensive performance, making it the preferred choice for covers in precision machinery and electronic equipment. As a medium-strength aluminum alloy, AL6061 is renowned for its excellent mechanical properties: superior machinability, outstanding corrosion resistance, and the ability to be heat-treated for further strength enhancement. Compared to other materials, AL6061 maintains lightweight characteristics while offering sufficient strength and rigidity—critical for aerospace, automotive, and automation equipment where weight is strictly regulated. Additionally, its ease of welding and compatibility with various surface treatments provide great flexibility in design and manufacturing, allowing it to adapt to complex application scenarios effortlessly.

In many cutting-edge applications, standardized covers often fail to meet specific functional and dimensional requirements, making customized processing the industry norm. CNC (Computer Numerical Control) machining technology, with its high precision and efficiency, has become the core process for manufacturing AL6061 covers. Through CNC machines, complex geometric shapes, hole positions, and threads from design drawings can be accurately transformed into physical products. From simple rectangular covers to irregular ones with intricate notches and curved surfaces, CNC machining handles all with ease.

This customized processing mode ensures covers perfectly match the host equipment, guaranteeing tight sealing and easy assembly. More importantly, it grants engineers extensive design freedom—optimizing cover thickness, structure, and hole positions based on specific application environments and functional needs to maximize performance.

An exceptional AL6061 cover relies not only on precise machining but also on meticulous surface treatment. Anodizing is a popular choice: it creates a dense, hard oxide film on the aluminum alloy surface through electrochemical reactions. This film significantly enhances corrosion and wear resistance while providing insulation. Moreover, adding different dyes during anodizing can infuse covers with vibrant colors—from classic black and silver to bold blue and red—greatly enriching aesthetic options.

Beyond anodizing, processes like sandblasting and brushing alter surface roughness, offering unique textures and visual effects. These treatments not only extend product lifespan but also enhance visual appeal, aligning with modern industrial design principles that balance functionality and aesthetics.

In precision machinery, tolerances and accuracy are core indicators of product quality. For AL6061 covers, dimensional precision—especially hole spacing and flatness—directly determines seamless integration with mating components, thereby affecting overall equipment performance and reliability. To achieve micron-level precision, manufacturers must use advanced CNC machines paired with high-precision measuring tools for real-time monitoring and calibration.

Factors like temperature, tool wear, and cutting fluid selection during processing impact final accuracy, requiring strict control over every step. For covers demanding high sealing performance, flatness control is critical: even minor warping or unevenness can cause air or liquid leakage, disrupting equipment operation. High-precision manufacturing not only tests equipment and technology but also embodies the producer’s meticulous craftsmanship.

Quality assurance is the final critical step in ensuring the reliability of each AL6061 cover. It involves a systematic inspection process spanning from raw material procurement to final product delivery.

Only covers passing all stringent tests receive certification and proceed to final assembly. This unwavering focus on quality control is not only a commitment to customers but also the foundation for safe, stable equipment operation.