Contact us

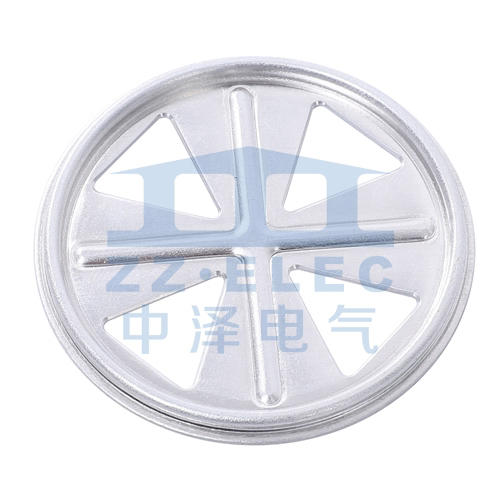

Common problems and solutions in the production of capacitor aluminum shells

Capacitor aluminum shells have achieved outstanding results in today's production. It not only drives the further development of the aluminum shell industry, but also has new breakthroughs in improving the overall use efficiency. However, it is inevitable that some operational problems will always occur in the production and processing of capacitor aluminum shells. In order to effectively solve these problems, let us look at the problems and solutions encountered in the processing of the capacitor aluminum shells.

First of all, the production of capacitor aluminum shells requires professional processing procedures, otherwise it is easy to cause irreparable defects in the production activities. The manufacturer also summarized some common problems in the long-term production, for example, the workpiece was placed in the sink for too long after oxidation. In the face of such problems, the manufacturer advocates timely dyeing work. If this situation has occurred, the workpiece can be placed in an anodizing tank or nitric acid neutralization tank for proper activation before dyeing. The effect will be very good.

Secondly, insufficient anodic oxide film thickness is also a type of problem that often occurs in capacitor aluminum casings. The solution is to check whether the anodizing process is standardized, and to see whether the temperature, voltage, conductivity and other factors are stable. If there is an abnormality, please adjust the specifications accordingly. If there is no abnormality, the oxidation time can be appropriately extended to ensure that the film thickness meets the standard. Of course, when using aluminum cans, they should not be mixed with iron and aluminum cookware. Mixing iron and aluminum cooking utensils is the most common thing, but such usage is extremely harmful to health.

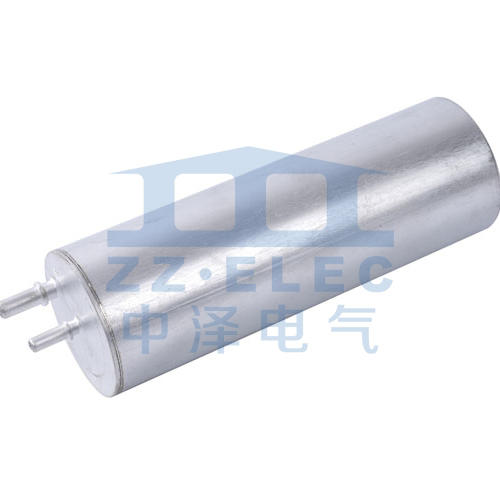

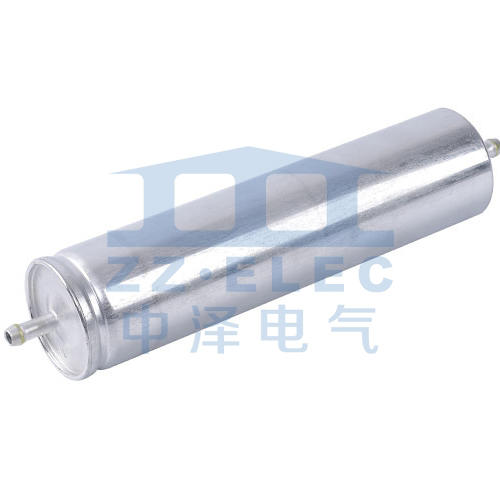

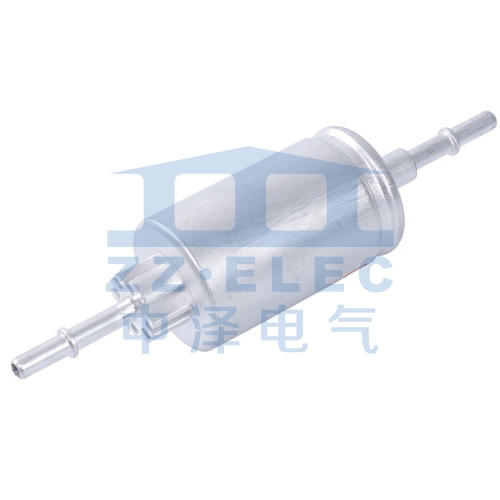

High quality VW IMPORT FILTER

Brand BMW FILTER

BMW (Import) 8 (E31), BMW (Import) ...

Land Rover (import) FREELANDER (LN)...

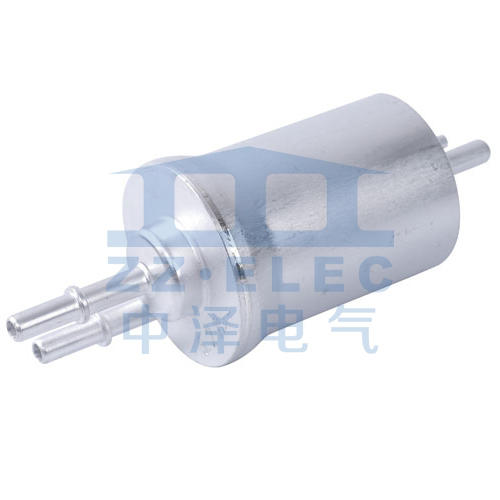

New POLO, Skoda, Audi A3, etc Filte...

Daewoo (import) REXTON (GAB_), Volk...

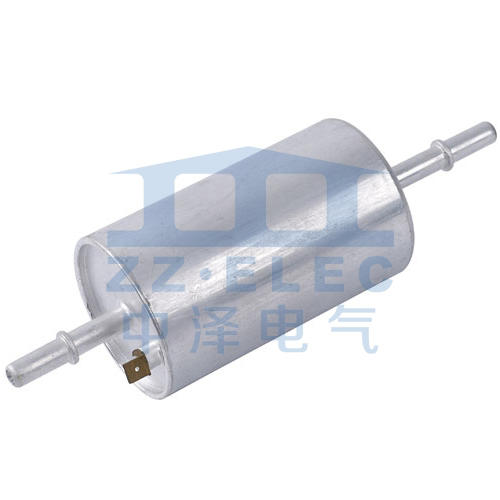

FORD(2011Focus) Filter

Fiat Filter

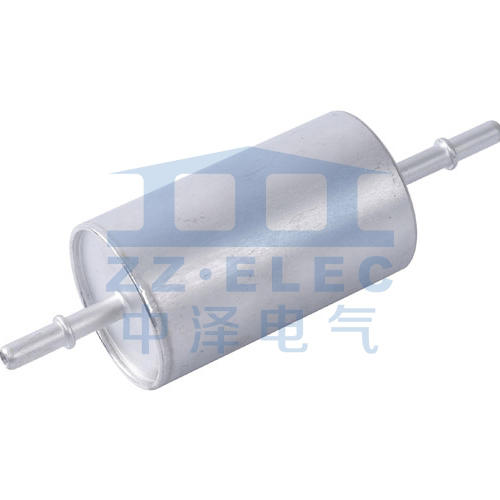

Fox Filter

Ford (import) FOCUS / Mazda (import...

POLO Filter

High Quality FORD (IMPORTED) FUSION...

AUDI-A7 Filter

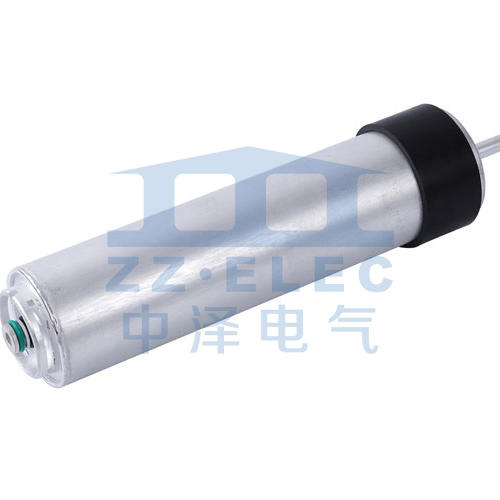

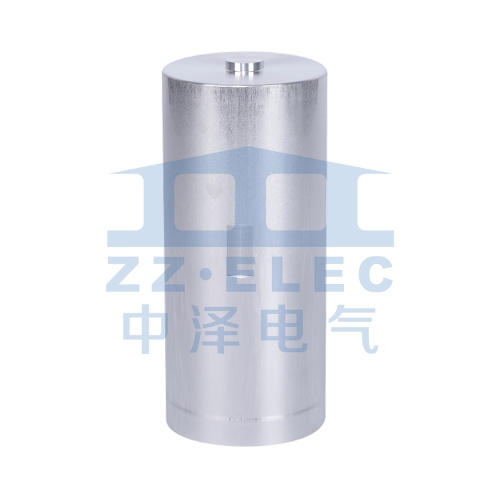

New energy super capacitor componen...

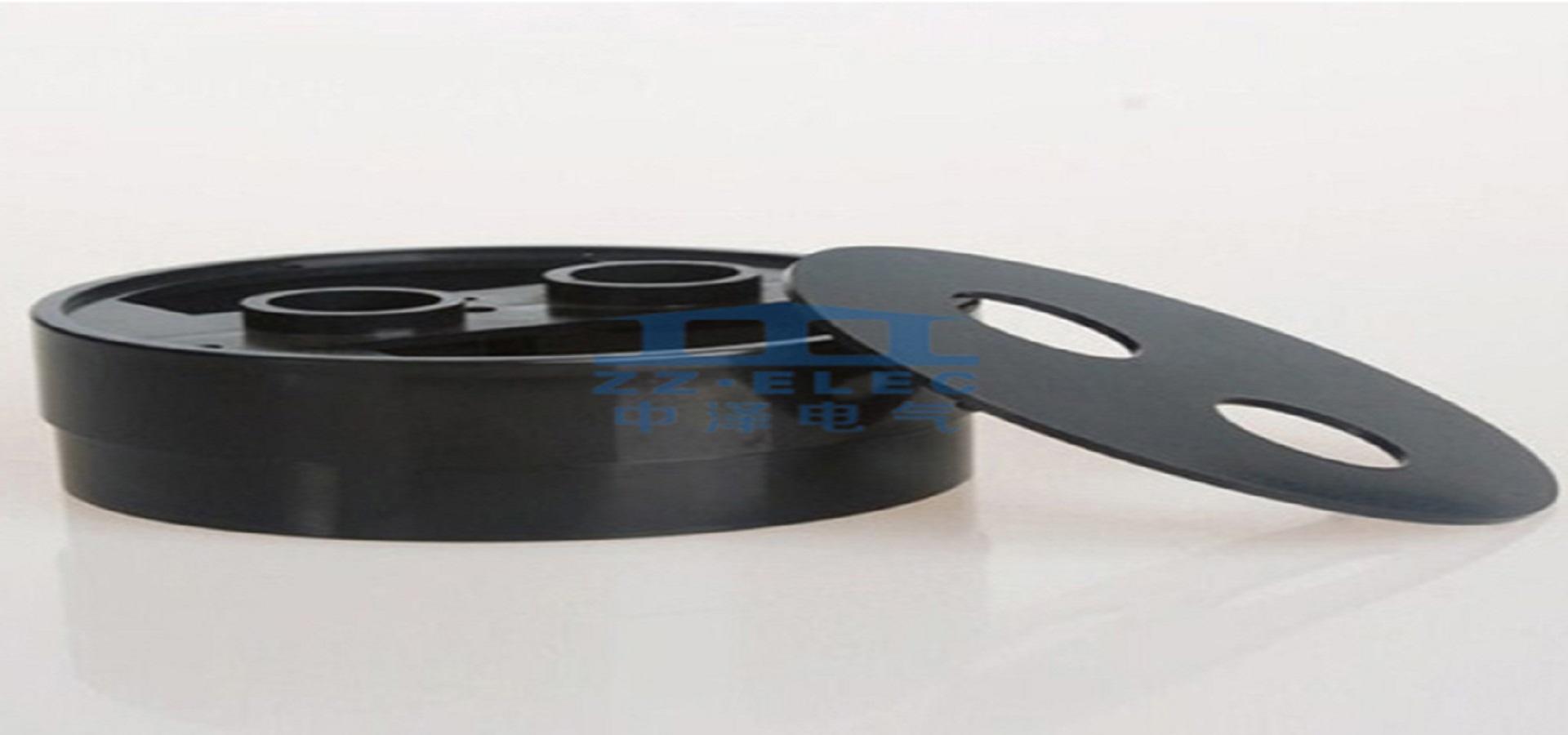

AL5052 POLE PIECE

Custom Precision POLE PIECE-8

Zhejiang Zhongze Electric Co., Ltd is a famous aluminium cold extrusions manufacturers and , our group has four production-type subsidiaries, which were first established in 1987 and started with precision cold extruded aluminum products and precision injection molded products.

Tel: +86 0573-82696969

Phone: +86 13957386455 13819772766

Fax: +86 573 82696982

E-mail: [email protected]

Add: 379 Yinhe Road, Jiaxing City, Zhejiang Province,China

Copyright © Zhejiang Zhongze Electric Co., Ltd. Rights Reserved. China Lithium battery Components Factory