Summary:Fuel filters play a crucial role in the efficient operation of internal combusti...

Fuel filters play a crucial role in the efficient operation of internal combustion engines, safeguarding their delicate components from contaminants that could compromise performance and longevity. Comprising several key components, fuel filters are meticulously designed to ensure optimal filtration while maintaining consistent fuel flow. In this article, we explore the essential components of a fuel filter and their functions in keeping engines running smoothly.

At the core of every fuel filter is the filter element itself, typically made of pleated paper, cellulose, or synthetic fibers. This element serves as the primary barrier against impurities such as dirt, rust, and debris present in the fuel. As fuel passes through the filter element, these contaminants are trapped, preventing them from reaching critical engine parts where they could cause damage or hinder performance.

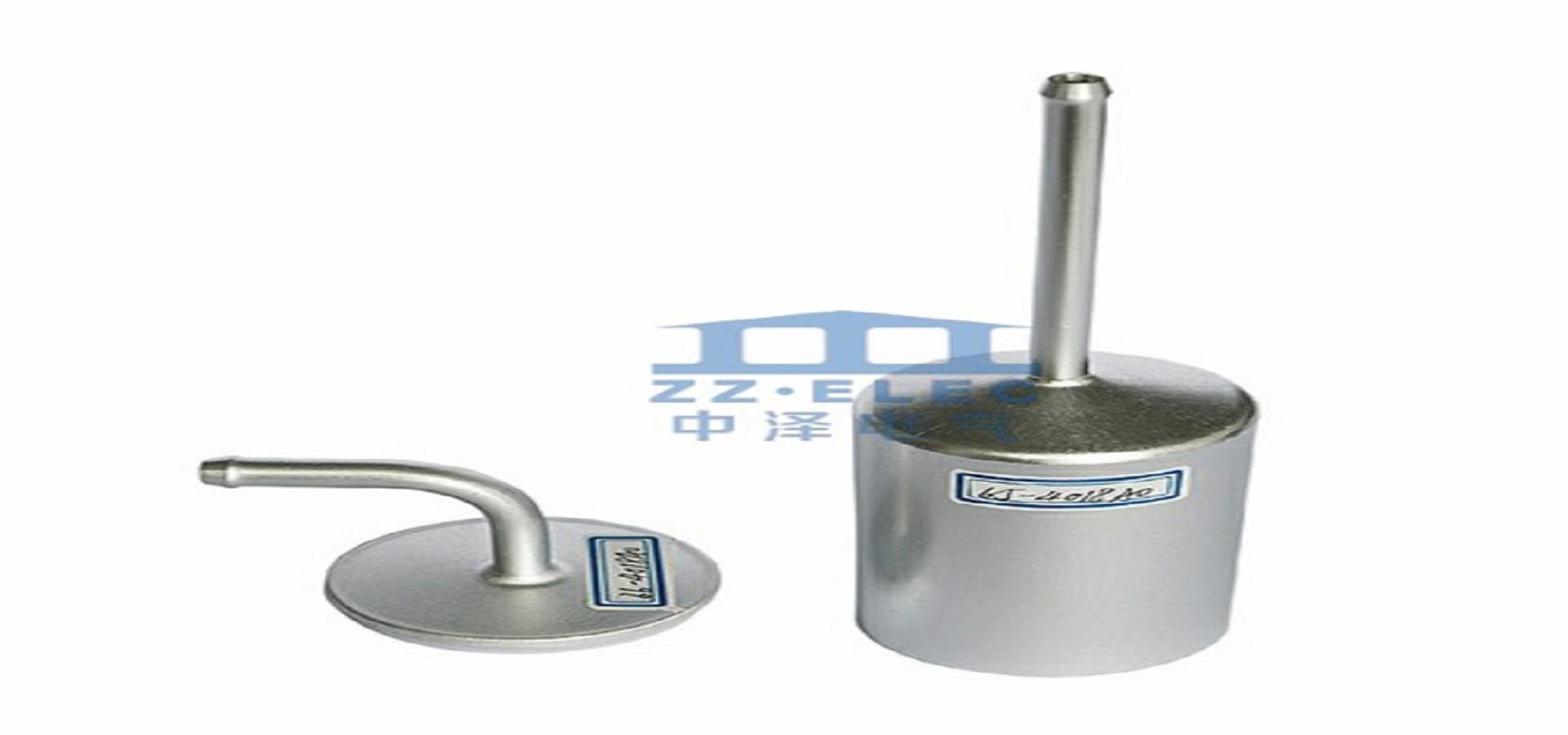

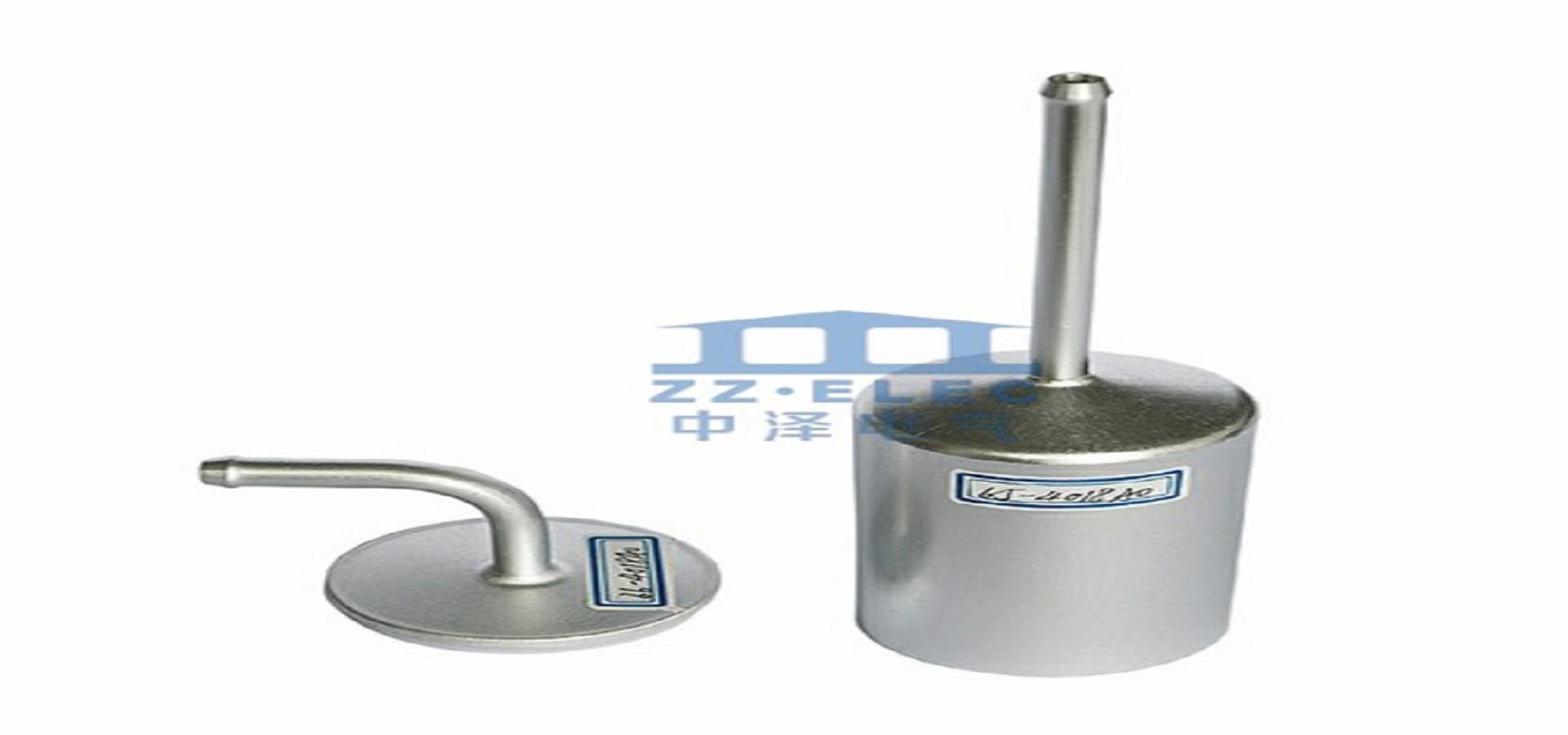

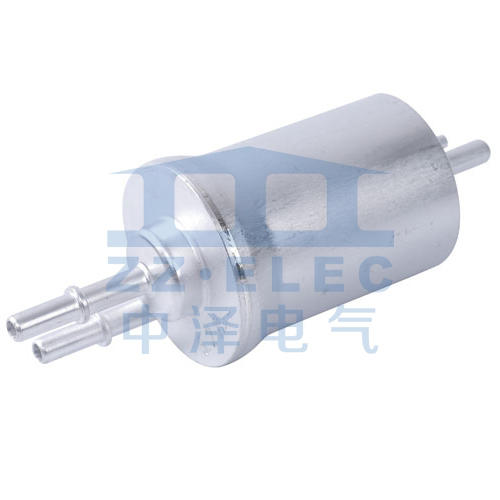

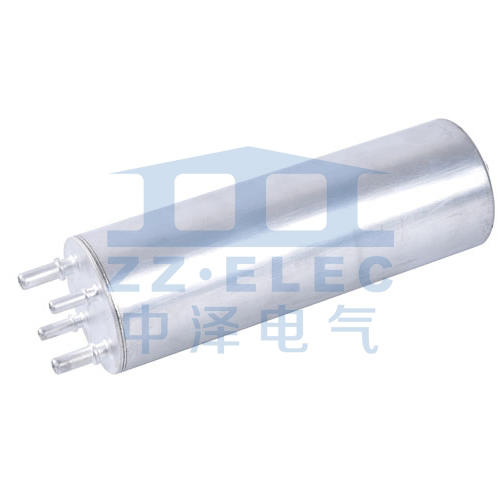

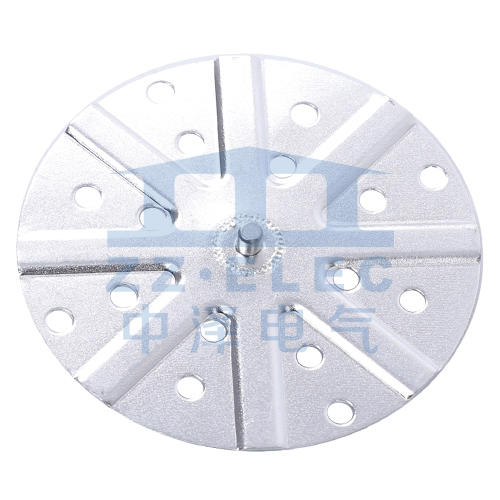

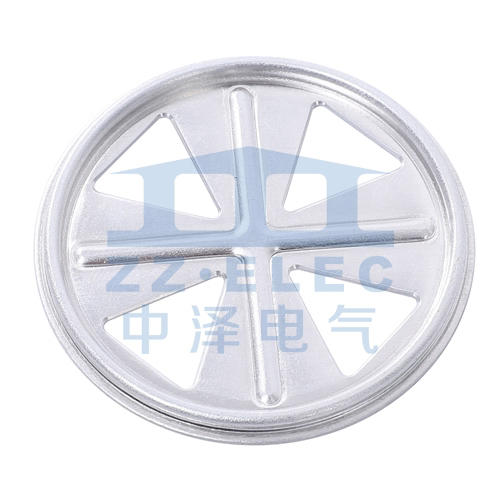

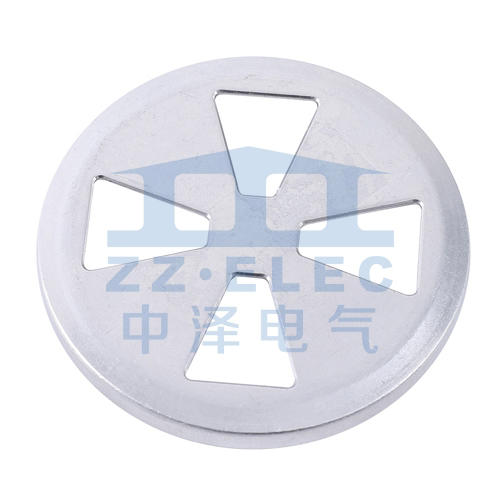

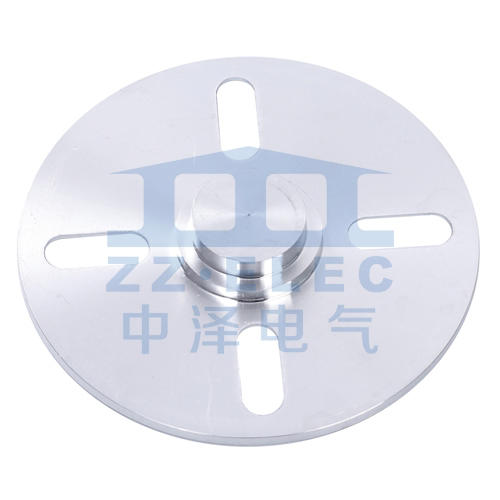

Surrounding the filter element is the filter housing, a sturdy casing that encloses and protects the filter media. Constructed from durable materials such as aluminum or steel, the housing provides structural integrity to the fuel filter, ensuring that it can withstand the rigors of engine operation and the pressures exerted by the fuel system. Additionally, the housing incorporates inlet and outlet ports that facilitate the seamless flow of fuel through the filter.

Another integral component of the fuel filter is the bypass valve, a safety feature designed to prevent fuel starvation in the event of a clogged filter element. When the filter becomes excessively obstructed, impeding the flow of fuel, the bypass valve opens to create an alternate pathway for fuel to bypass the filter element temporarily. While this compromises filtration efficiency, it ensures that the engine continues to receive an adequate supply of fuel, preventing stalling or engine damage.

In addition to the filter element and housing, fuel filters may also incorporate other components to enhance their performance and functionality. Anti-drain back valves, for instance, prevent fuel from draining out of the filter when the engine is turned off, ensuring immediate fuel delivery upon startup and preventing dry starts. Similarly, water separators may be integrated into fuel filters to remove moisture from the fuel, protecting the engine from corrosion and fuel system malfunctions.

The efficiency and longevity of a fuel filter depend not only on the quality of its components but also on regular maintenance and replacement intervals. Over time, the filter element becomes saturated with contaminants, diminishing its filtration capacity and impeding fuel flow. To ensure optimal engine performance and reliability, fuel filters should be inspected and replaced according to the manufacturer's recommendations.